Inspection Cycle Time per Vehicle is less than a Minute.

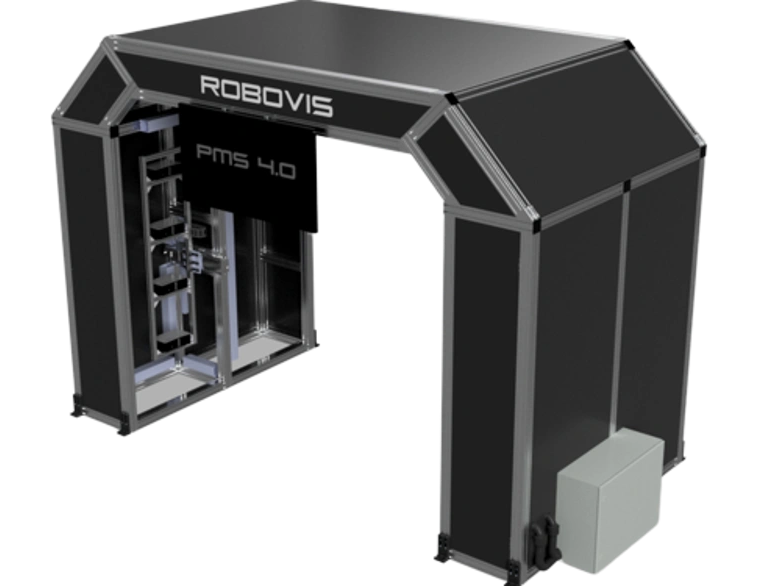

BridgeScan

The Ultimate Guardian of Automotive Excellence: A Universal Solution for Paintshop, Bodyshop, and QMS Inspections.

Applications

Paintshop

Quality Management / Assembly

Paintshop

Revolutionizing Quality Assurance in Automotive Painting: Introducing Our Advanced Bridge System with Cutting-Edge Vision Sensors.

Bodyshop

Quality Management / Assembly

Paintshop

Pioneering Precision in Pre-Paint Inspection: Our Advanced Bridge System with Integrated Vision Sensors for Bodyshops .

Quality Management / Assembly

Quality Management / Assembly

Quality Management / Assembly

Setting the Gold Standard in Final Inspection: The Bridge System with Precision Vision Sensors for QMS by the end of Assembly.

BridgeScan for Paintshops for 100% Quality Inspection

Elevating Automotive Aesthetics: The Future of Paint Inspection

Precision Meets Performance: The Bridge System's Vision for Flawless Paint Jobs

Precision Meets Performance: The Bridge System's Vision for Flawless Paint Jobs

In the dynamic landscape of car manufacturing, every detail counts. The paint finish, integral to a vehicle's beauty, often faces challenges from unnoticed imperfections. With our groundbreaking Bridge System, embedded with up to 15 advanced vision sensors, we're setting new standards in paint inspection, ensuring that every vehicle showcases perfection.

Precision Meets Performance: The Bridge System's Vision for Flawless Paint Jobs

Precision Meets Performance: The Bridge System's Vision for Flawless Paint Jobs

Precision Meets Performance: The Bridge System's Vision for Flawless Paint Jobs

The art of automotive painting demands precision, and even the smallest flaw can impact a vehicle's visual appeal. Introducing our Bridge System - the pinnacle of inspection technology. Its ability to detect and categorize even the minutest paint issues guarantees a flawless finish every time.

Beyond Aesthetics: Ensuring Longevity with Our Advanced Bridge System

Precision Meets Performance: The Bridge System's Vision for Flawless Paint Jobs

Beyond Aesthetics: Ensuring Longevity with Our Advanced Bridge System

While a paint job's beauty is evident, its durability is equally crucial. Imperfections can shorten the lifespan of a vehicle's appearance. Our innovative Bridge System, boasting up to 15 vision sensors, ensures both stunning and lasting finishes, redefining quality benchmarks in automotive painting.

Transformative Tech for Perfect Paintshops: The Bridge System

From Tiny Scratches to Seamless Surfaces: Detecting Every Imperfection

Beyond Aesthetics: Ensuring Longevity with Our Advanced Bridge System

The paintshop has always been a critical checkpoint for vehicle quality. With the integration of our state-of-the-art Bridge System, paint inspections are elevated. Seamlessly fitting into any production process, our solution ensures that every vehicle emerges with an immaculate finish.

From Tiny Scratches to Seamless Surfaces: Detecting Every Imperfection

From Tiny Scratches to Seamless Surfaces: Detecting Every Imperfection

From Tiny Scratches to Seamless Surfaces: Detecting Every Imperfection

In the world of automotive finishes, even the smallest scratch matters. Our Bridge System offers a visionary approach to paint inspection. Meticulously scanning the entire vehicle surface, it identifies every blemish, ensuring vehicles leave the production line with unparalleled elegance.

Charting the New Course in Paint Quality Assurance

From Tiny Scratches to Seamless Surfaces: Detecting Every Imperfection

From Tiny Scratches to Seamless Surfaces: Detecting Every Imperfection

Step into the future of automotive paint inspections with our cutting-edge Bridge System. Designed for both small-scale and large manufacturers, this system identifies and classifies defects with unmatched accuracy. Trust in a solution that minimizes rework and maximizes perfection.

BridgeScan for Bodyshop for 100% Quality Inspection

Mastering the Craft: Pre-Paint Inspections Redefined

From Weld to Wonder: Precision-Centric Inspections for Automotive Mastery

The Welding Wizard: Our Bridge System's Eye for Detail

Automotive artistry begins with impeccable welding craftsmanship. It's this foundation that ensures a stellar paint finish. The heart of this perfection? Our Bridge System. Equipped with up to 15 advanced vision sensors, it promises pristine inspections in bodyshops, raising the bar of excellence.

The Welding Wizard: Our Bridge System's Eye for Detail

From Weld to Wonder: Precision-Centric Inspections for Automotive Mastery

The Welding Wizard: Our Bridge System's Eye for Detail

Every vehicle's story starts with its skeletal framework, meticulously welded. Imperfections at this stage can mar the painting finish. Our cutting-edge Bridge System steps in here, scanning each vehicle post-welding, ensuring that every inch is primed for the perfect paint job.

From Weld to Wonder: Precision-Centric Inspections for Automotive Mastery

From Weld to Wonder: Precision-Centric Inspections for Automotive Mastery

From Weld to Wonder: Precision-Centric Inspections for Automotive Mastery

The intricacies of automotive manufacturing demand stringent quality checks, especially post-welding. Our advanced Bridge System acts as the vigilant quality gatekeeper, identifying even the slightest irregularities. It's our pledge to ensure every vehicle is nothing short of a masterpiece.

Flexibility & Finesse: Tailored Inspections for Every Bodyshop

Harnessing Tech for Automotive Excellence: The Bridge System Promise

From Weld to Wonder: Precision-Centric Inspections for Automotive Mastery

Whether churning out vehicles in bulk or crafting custom creations, our Bridge System adapts. Offering configurations with 12 or 15 vision sensors, it marries flexibility with precision, assuring every automotive body is prepped and primed to perfection.

The Integrity Imperative: Perfecting Vehicles from the Ground Up

Harnessing Tech for Automotive Excellence: The Bridge System Promise

Harnessing Tech for Automotive Excellence: The Bridge System Promise

A flawless paint job begins with impeccable welding. Our Bridge System ensures this foundation is unblemished. By focusing on the critical post-welding stage, it guarantees that every vehicle isn't just painted but painted to perfection.

Harnessing Tech for Automotive Excellence: The Bridge System Promise

Harnessing Tech for Automotive Excellence: The Bridge System Promise

Harnessing Tech for Automotive Excellence: The Bridge System Promise

At the crossroads of innovation and craftsmanship lies our transformative Bridge System. Ensuring every vehicle's body is free from post-welding defects, it stands as a testament to our commitment to quality. Dive into a world where technology and precision craft automotive perfection together.

BridgeScan for Assembly for 100% Quality Inspection

Craftsmanship Culmination: The Bridge System's Assurance at Assembly's End

Craftsmanship Culmination: The Bridge System's Assurance at Assembly's End

Craftsmanship Culmination: The Bridge System's Assurance at Assembly's End

Every vehicle's creation journey has one ultimate checkpoint: the final inspection at the QMS. Our revolutionary Bridge System, armed with up to 15 vision sensors, stands as this definitive gateway, ensuring that vehicles aren't merely built but sculpted to perfection.

Marrying Tech and Craft: Precision Inspections for Modern Automotive

Craftsmanship Culmination: The Bridge System's Assurance at Assembly's End

Craftsmanship Culmination: The Bridge System's Assurance at Assembly's End

The path from raw material to automotive marvel is paved with precision. With our state-of-the-art Bridge System, this dedication to detail reaches its zenith. Experience inspections that go beyond mere checks, embracing the art and science of flawless assembly.

Beyond Assembly: Defining Perfection with Our Advanced Bridge System

Craftsmanship Culmination: The Bridge System's Assurance at Assembly's End

Beyond Assembly: Defining Perfection with Our Advanced Bridge System

A vehicle's assembly is an intricate dance of parts and processes. Our Bridge System captures the essence of this craftsmanship, examining every nuance with unmatched accuracy. Elevate the quality assurance standard, ensuring each vehicle emerges as a masterpiece.

The Epitome of Inspection: Tailored Precision with the Bridge System

The Epitome of Inspection: Tailored Precision with the Bridge System

Beyond Assembly: Defining Perfection with Our Advanced Bridge System

Whether it's a bespoke luxury vehicle or a model for the masses, quality remains paramount. Our adaptable Bridge System, with its 12 or 15 vision sensor options, merges flexibility with finesse, setting the gold standard for end-of-assembly inspections across all production scales.

The Final Touch: Unwavering Quality Assurance in Vehicle Assembly

The Epitome of Inspection: Tailored Precision with the Bridge System

Championing Craftsmanship: The Bridge System's Pledge to Perfection

The assembly line's conclusion shouldn't just be an end, but a climax of precision. With the Bridge System, it's not just about inspection, but the celebration of craftsmanship. Embrace a system that guarantees the embodiment of excellence in every vehicle.

Championing Craftsmanship: The Bridge System's Pledge to Perfection

The Epitome of Inspection: Tailored Precision with the Bridge System

Championing Craftsmanship: The Bridge System's Pledge to Perfection

From the first component to the final quality check, excellence should be the constant companion. Our Bridge System, with its cutting-edge technology, reiterates this commitment at the pivotal QMS checkpoint, amplifying the precision and pride that your brand stands for. Choose perfection; choose the Bridge System.

Create Your OWN Defect Catalogue with Our AI Based PMS Technology

Customizable Defect Catalogue Specific to Production Requirements

Black-Spot

Craters

Pinhole

Pit

Dirt

Hidding Power

Loss of Gloss

Loss of Adhesion

Scratch

Mottling

Splay

Orange Peel

Overspray

Popping

Polishing Marks

Sagging

Sand Paper Marks

Contamination

Seeds

Solvent Boil

Oven Inclusions

Dents

Blister

...and more

Contact us for more information.

Defect Catalogues are generated with AI Classification Toolbox specific to Customer's Production Procedures.

Contact Us for Free-of-charge sample test with our experts

Better yet, see us in person!

We love our customers, so feel free to visit during normal business hours.

ROBOVIS AI-LABS

Copyright © 2024 ROBOVIS AI-labs - All Rights Reserved.

Powered by ROBOVIS